Stone masonry is the skilled craft of shaping, laying, and bonding natural stone to form structural as well as decorative building elements. It blends knowledge of materials with hands-on workmanship to produce long-lasting, weather-resistant surfaces.

In this guide, we set out what stone masonry involves, the key materials and techniques used in both construction and conservation, and why correct stone restoration matters for property value, appearance, and durability, especially across London’s older streets and monuments.

You’ll find clear descriptions of the main masonry types, an overview of traditional and modern conservation methods, and practical steps owners should take when assessing damage or planning repairs.

What Is Stone Masonry And Why Is It Important?

Stone masonry is the construction or repair of building elements using cut or shaped natural stone laid in mortar and set to carry structural loads and resist the weather.

Shaped stone delivers compressive strength, while correctly specified mortar and jointing allow movement and vapour permeability; together, these factors protect the fabric and appearance of a building.

Stone masonry matters for structural stability, aesthetic character, and heritage value: correctly executed work preserves façades, cornices, and lintels, and preserves the original architectural intent.

Choosing compatible materials and skilled workmanship reduces long-term maintenance and avoids the damage that can follow incompatible repairs. Understanding these basics helps owners recognise when professional intervention is needed to prevent accelerated deterioration.

Craftsmanship And Durability In Stone Masonry

Good stonework starts with precise dressing, cutting, and bedding so each unit sits flat and transfers loads without point stresses that cause cracking.

Experienced stonemasons shape faces, form joints, and match tooling marks to get a secure fit and an authentic finish; that attention to detail, combined with appropriate mortars and ongoing maintenance, is why many historic buildings endure for centuries.

Durability depends on matching stone properties, porosity, density, and freeze-thaw behaviour to the local environment, and on jointing and surface finishes that shed water and limit salt ingress.

Historic church walls and Georgian façades show how hand-worked ashlar and lime mortars perform over time in ways that rigid cement repairs often cannot. In short, material knowledge and craft skills are both essential to long-lasting results. Charlotte Church’s home renovation stress highlights the challenges faced by homeowners when undertaking such projects. Balancing aesthetic desires with structural integrity can often lead to overwhelming decisions. Nonetheless, understanding the properties of each material can significantly alleviate the pressure and ensure the renovation stands the test of time.

Materials And Tools Used In Stone Masonry

Stone masonry works with a specific palette of materials and tools chosen for in-situ compatibility and performance. In London projects, you commonly see Portland stone, Bath stone, and Yorkstone, each selected for colour, workability, and weather resistance.

Lime mortar remains the conservation standard because it lets walls breathe and move slightly. Tools range from traditional chisels, mallets, and pitching tools for hand finishing to diamond saws, grinders, and pneumatic chisels for faster, precise cutting; 3D scanning and CNC routing now help reproduce complex mouldings accurately.

Operatives also use respiratory protection, dust extraction, and PPE when cutting or cleaning. Selecting the right stone, mortar, and tooling ensures repairs are sympathetic, durable, and, where required by conservation principles, reversible.

What Are The Main Types Of Stone Masonry?

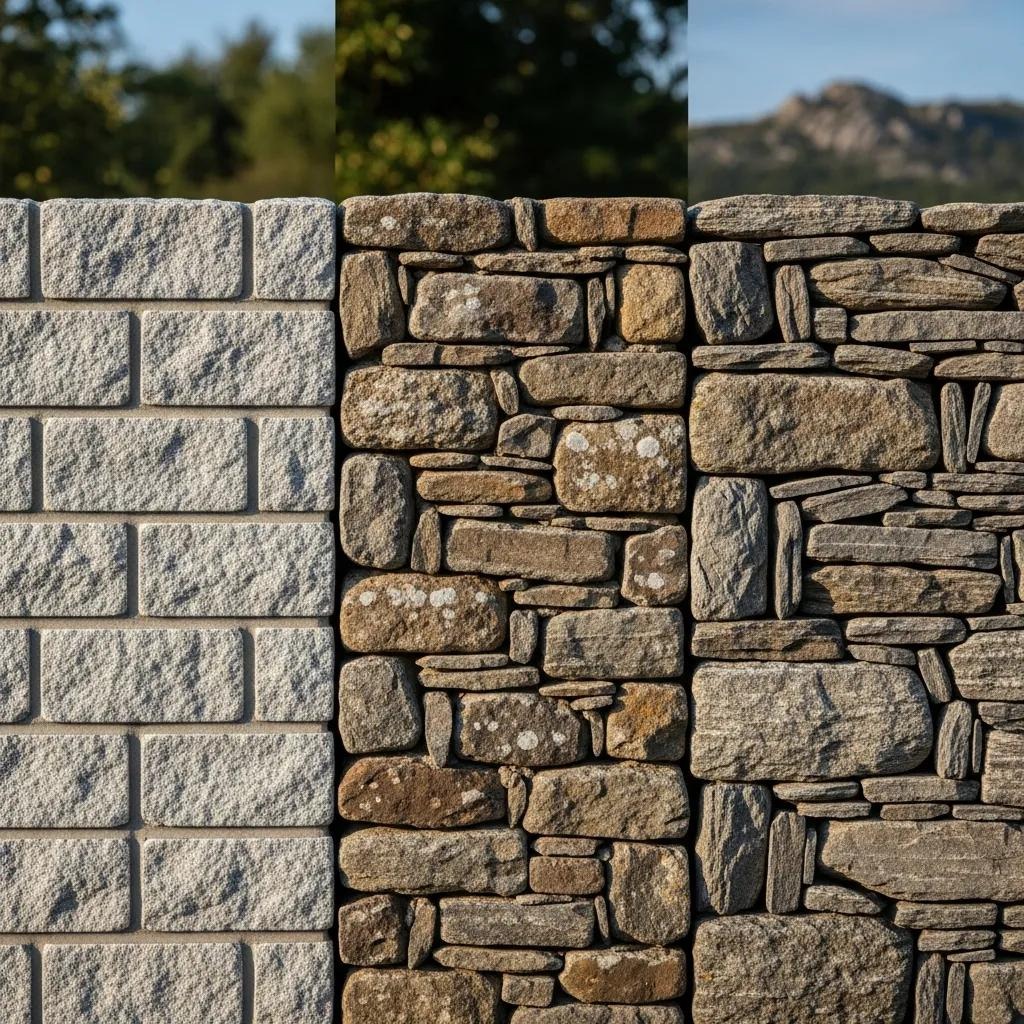

Stone masonry covers several construction types, defined by how stones are prepared, laid, and finished to meet structural or visual aims. The main forms include rubble masonry, ashlar, dry stone, polygonal masonry, and coursed rubble. They differ in precision, finish, and typical applications, from rough retaining walls to finely dressed façades.

Knowing these differences helps owners and designers select the right repair approach, understand the required craftsmanship, and set realistic costs. The comparative table below summarises materials, typical uses, strengths, and limitations for quick reference.

Various masonry styles suit different structural and visual roles; use the table to match building needs to the appropriate approach.

| Masonry Type | Typical Materials | Typical Use | Strengths | Limitations |

|---|---|---|---|---|

| Ashlar | Dressed natural stone blocks | High‑quality façades, historic elevations | Precise fit, refined appearance, strong load capacity | Higher cost; requires matching stone for repairs |

| Rubble (coursed/uncoursed) | Rough‑hewn or irregular stones | Retaining walls, vernacular buildings | Economical, robust, uses local stone | Irregular appearance; needs careful pointing |

| Dry Stone | Un-dressed stone, no mortar | Retaining and landscape walls | Flexible, durable, good drainage, low maintenance | Labour‑intensive; limited for high vertical loads |

| Polygonal | Irregularly shaped stones cut to fit | Decorative walls and cladding | Distinctive pattern; visually adaptable | Complex to execute; needs experienced masons |

This comparison highlights trade‑offs: ashlar suits prestigious façades where precision matters, while rubble types are appropriate for more utilitarian or rustic situations. Choosing the right approach reduces the need for disruptive future repairs.

Rubble Masonry And Its Variations

Rubble masonry uses undressed or roughly shaped stones laid in mortar, where a uniform face isn’t required. Variations include uncoursed rubble, with a random look, and coursed rubble, where stones are roughly grouped into levels for a more ordered appearance; polygonal rubble fits interlocking irregular shapes for decorative effect.

You’ll often find rubble in garden retaining walls, boundary walls, and vernacular buildings where local stone dictated the form. Repairs focus on removing failed mortar, repointing with compatible lime mixes, and replacing only the most degraded stones to preserve original fabric. In addition to these repairs, it’s essential to check for signs of structural damage in buildings that may compromise their stability. Regular inspections can help identify issues early, allowing for timely interventions that safeguard the integrity of these structures. By addressing these concerns proactively, the longevity of the buildings can be significantly enhanced.

When done correctly, rubble repairs retain character while improving stability and weather resistance.

How Ashlar Masonry Differs From Other Types

Ashlar uses precisely dressed blocks with smooth faces and uniform joints to create a high-quality planar façade, commonly seen in Georgian and Victorian work. Unlike rubble, ashlar requires exact stone cutting and bedding to maintain tight joints and regular lines; the result is both visually refined and structurally efficient.

In restoration, ashlar repairs demand careful stone matching, in colour, grain, and tooling, to avoid patchiness. Mortar choice is equally important: lime-based mixes preserve breathability and allow micro-movement, whereas cement mortars can trap moisture and accelerate decay.

Effective ashlar conservation, therefore, blends technical precision with sympathetic aesthetic matching.

Which Stone Masonry Techniques Are Used In Restoration And Construction?

Projects combine time‑honoured craft and contemporary technology to meet conservation goals and modern performance needs. Traditional methods, hand dressing, lime repointing, and like‑for‑like piecing‑in- prioritise material compatibility and minimal intervention. Modern techniques, diamond sawing, CNC routing, and 3D scanning, add speed and precision.

The right choice depends on stone type, the building’s conservation status, and whether the aim is structural stabilisation, aesthetic renewal, or both. The table below compares common techniques, when to use them, and their benefits and limitations to help owners and project teams decide.

Use this practical comparison to guide technique selection based on purpose and constraints.

| Technique | When Used | Benefits | Limitations |

|---|---|---|---|

| Lime repointing | Heritage stonework with breathable masonry | Restores joint integrity and maintains vapour permeability | Requires specialist skills; slower curing than cement |

| Hand dressing | Matching historic profiles and tooling marks | Authentic appearance; precise fit | Time‑consuming; labour‑intensive |

| Diamond sawing / CNC | Complex replacements and precise mouldings | High accuracy; repeatable profiles | Capital‑intensive; may need hand finishing to blend |

| Consolidation (stone repair) | Fragile or friable stone faces | Stabilises surfaces and prolongs life | Needs compatible consolidants and prior testing |

Traditional Techniques In Heritage Stonemasonry

Heritage stonemasonry emphasises hand skills, lime mortars, and conservation ethics that favour repair over wholesale replacement.

Typical techniques include careful hand dressing to match original tooling, sensitive lime repointing to respect vapour permeability, and piecing‑in where only the decayed portion is replaced with matched stone.

Conservation principles, minimal intervention, reversibility, and clear documentation ensure future generations can read the building’s history and that later work remains possible.

These approaches require experienced masons and often liaison with conservation officers to meet best‑practice standards. Practitioners balance authenticity with durability to keep historic fabric stable and legible.

Correctly specified lime mortar is central to the long‑term health of historic buildings, particularly in exposed locations.

Modern Techniques That Improve Stone Masonry Precision

Modern tools,3D scanning, CNC routing, and diamond cutting, complement traditional craft by reproducing complex mouldings accurately and producing replacement units more quickly. These technologies reduce the margin for error and free masons to concentrate on hand finishing, colour matching, and final fitting.

For conservation, digital surveys help record existing conditions and plan minimally invasive interventions; CNC pieces can then be hand‑tooled to match historic texture. That said, machine work should be used judiciously, too much machine finish without hand finishing can look intrusive or fail to accommodate subtle site‑specific variations.

Why Is Professional Stone Masonry Essential For London’s Heritage Buildings?

Professional stone masonry is crucial in London because the city contains many sensitive heritage buildings made from stone that react to urban pollution, past alterations, and strict planning controls. Specialists know local materials, Portland, Bath, and other building stones, and understand how pollution causes black crusts, salts, and surface erosion.

They also recognise the risks posed by inappropriate cementitious repairs that can trap moisture and speed deterioration. A professional, evidence‑based approachmaterial analysis, trial repairs, and controlled cleaning, protects the building’s fabric and its market and cultural value.

Engaging experienced contractors reduces the risk of costly repeat work and helps preserve the character that defines London’s streetscapes.

Successful repair hinges on a thorough understanding of the existing structure, its materials, and the root causes of damage, as demonstrated by conservation best practice

Challenges Facing London’s Historic Properties

London’s historic buildings face a mix of environmental and human factors that accelerate stone decay and complicate repairs. Pollution creates black crusts and soiling on calcareous stones; salts from de‑icing or coastal air lead to flaking and delamination; and freeze‑thaw cycles worsen surface loss.

Past repairs using cement mortars often form rigid joints that trap moisture and cause internal damage.

Hidden movement, timber decay, or poor drainage can show up as cracked stonework, and harsh cleaning methods can strip protective patinas. Accurate diagnosis, sampling, petrographic analysis, and moisture mapping are a necessary first step to avoid interventions that make conditions worse.

How Expert Stone Restoration Preserves Architectural Legacy

Good restoration follows an evidence‑based programme: survey and testing before intrusive work, use of compatible materials such as lime mortars or matched stone, and minimal intervention to retain original fabric.

Typical steps include removing failed mortar, consolidating friable stone, sourcing matching stone for piecing‑in, and repointing with lime to restore cohesion and breathability; finishing reproduces original tooling to maintain visual continuity.

These methods restore stability and harmony while making future maintenance manageable. Combining technical assessment with craft‑led execution preserves both the building and the historical stories written in its masonry. Incorporating restoration techniques for historic homes not only enhances the aesthetic value but also contributes to energy efficiency and sustainability. Each project can greatly benefit from skilled artisans who understand traditional methods, ensuring that every detail is meticulously attended to. By embracing innovation alongside these techniques, homeowners can achieve a perfect balance between modern living and historical integrity.

Environ Restoration Services specialises in restoring, repairing, and refurbishing traditional, heritage, and high‑end properties across London.

We start with a detailed restoration survey and diagnostic testing to establish causes of failure, then prepare a clearly scoped proposal recommending like‑for‑like repairs, lime repointing where needed, piecing‑in matched stone, or targeted consolidation.

Our team blends traditional craftsmanship with modern diagnostics to balance authenticity and longevity. Clients can request a survey or quote for a bespoke assessment that outlines recommended works, timescales, and expected outcomes so they can make informed conservation decisions.

Frequently Asked Questions

What Are The Benefits Of Using Lime Mortar In Stone Masonry?

Lime mortar is preferred for stone and heritage buildings because it is breathable and flexible. Unlike cement, lime lets moisture escape from the wall and accommodates small movements without cracking, reducing the risk of spalling and decay. Its compatibility with natural stone helps preserve both the structural and visual qualities of historic masonry.

How Can I Identify Whether My Stone Masonry Needs Repair?

Look for visible cracks, loose or missing stones, or crumbling mortar. Damp patches, efflorescence (white salt deposits), or active water ingress are also warning signs.

Regular inspections will catch many problems early; if you spot deterioration such as flaking stone or staining, arrange a professional assessment to identify the cause and the right repair approach.

What Is The Role Of A Stonemason In Restoration Projects?

A stonemason assesses existing stonework, selects compatible materials, and carries out repair work that respects the original craftsmanship. Tasks include hand dressing, lime repointing, and piecing‑in matched stone so the repair preserves structural stability and blends visually with the original fabric.

What Are The Common Challenges Faced During Stone Restoration?

Typical challenges include matching the original stone’s colour, texture, and tooling marks; resolving moisture problems such as trapped water or salt migration; and undoing inappropriate past repairs, often cementitious, that can trap moisture. Careful assessment and planning are essential to select compatible materials and avoid further damage.